Coil Winding Nozzle Introduction

Air Wipes

Bow Guide

Carbide Guides

Eyelet Guides

Nozzle Guides

Pulleys

Ring Guides

Rods

Roller Guides

Snail Guides

Tube Guides

U- Guides

Welding Butts

Surface Finish

Glossary

Inquiry Forms

Materials

Site Map

Fabricating a 0.1 mm bore in tungsten carbide is now a routine practice at COSMOS. This is what the state-of-the-art miniature coil winders demand and to which we responded with a Solid Tungsten Carbide nozzle of a Diamond Polished Bore of 0.1 mm plus precise radius dedicated for winding insulated wire as fine as Ø 0.025m m, which is about a quarter of the width of a human hair.

Precise Radii Assurance

In unison with the trend to miniaturize, the tolerance of the bore radii has become even tighter. The standard radii tolerance that we presently offer is +/- 0.10 mm.

Upon request, our nozzle department will accompany each shipment with a quality assurance report that registers the radius dimension of each nozzle based upon which our customers may and do select at random to inspect, destructively, as shown above, in middle. To date we have yet to receive a response of inconsistency.

Why Tungsten Carbide and not steel?

Is a carbon or stainless steel nozzle cheaper and capable of being salvaged when bent?

Answer: The choice of the nozzle material is a matter of the manufacturing philosophy. Many nozzle makers claim that a steel nozzle is cheaper, can also be mirror finished and they do not break on impact and can always be put back after rectifying.

The truths are:

1. You need to examine the bore surface under a microscope to see the true picture

2. A salvaged steel nozzle creates insulation layer damages, which leads to catastrophic consequences

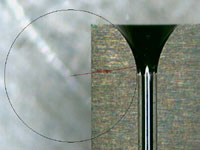

The photo microscopic image at top right may be of reference value. This is a stainless steel nozzle, bent and salvaged.

Upon cut-away and examination under a microscope, a bulge is revealed at the point where the nozzle was bent. Wire insulation is impaired by the bulge and may go undetected, only to manifest itself years after the coil has been put into service, resulting in millions of recalls and replacements.

The bore surface in the photo reveals the inherent nature of all hard-drawn ferrous tubes, where steel grains line up in the direction of drawing, creating a rough texture that is difficult to level.

On the other hand, the cost of a Tungsten Carbide Nozzle is 2 - 3 times that of the steel nozzle. The choice is yours.

Ruby Tipped Tungsten Carbide The Numbering System The Drawings Product Gallery ( 1 )